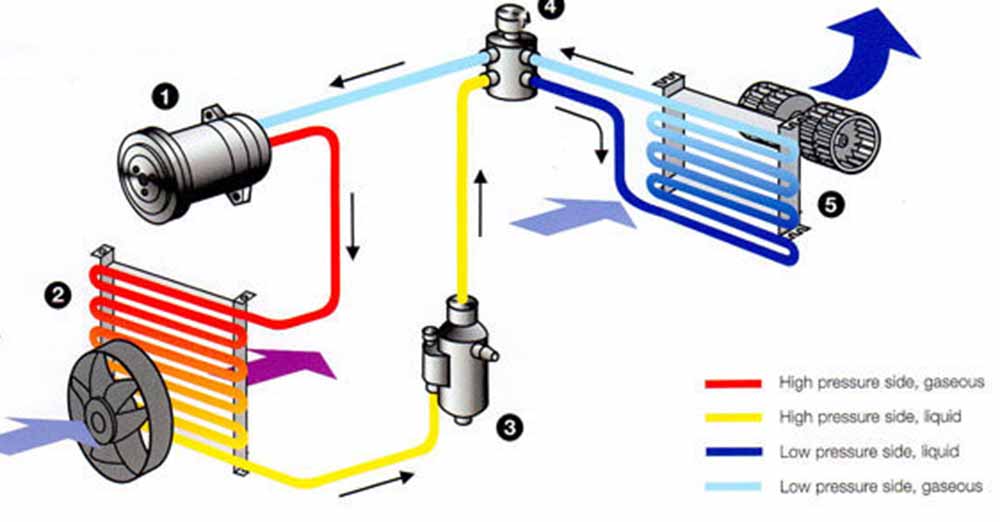

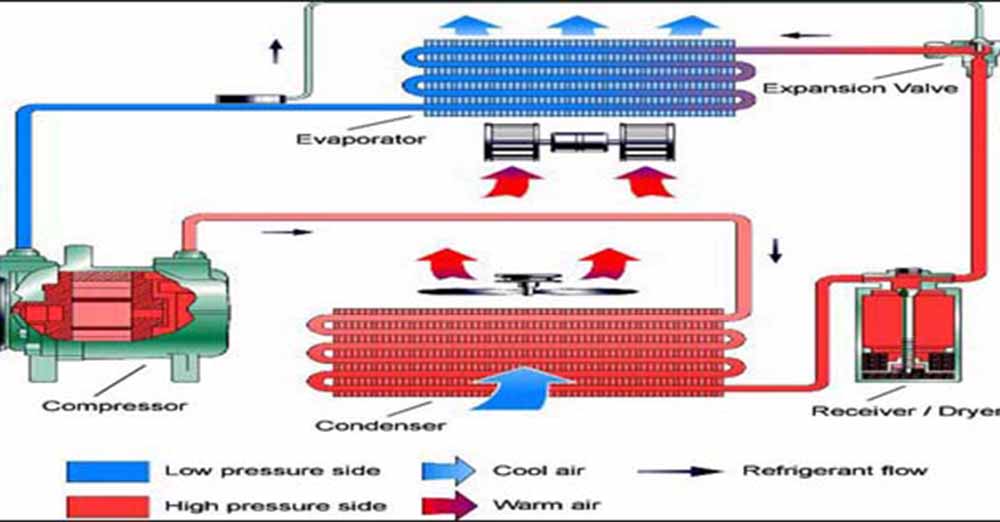

Before finding the fault, it is important to understand the theory of how the air corn system works. When reading the high-pressure gauge and low pressure gauge, if it is High 250 Low 50, the system is overcharged or there is a fault in the condenser, so the system will be recharged. When reading the high-pressure gauge and the low pressure gauge, if it is High 160 Low 10, the evaporator must be frosted.

The low-pressure pipelines must be checked. The expansion valves must be checked. Comparing High side and Low side, if High 225 Low 80, expansion valve must be checked, heat sensitizing tube must be checked. If it is High 50 Low 50, check if the compressor clutch is engaged. If the refrigerant pressure sensor is bad, it will not engage. If there is no gas, the compressor clutch will not engage.

There is also a fault in the wiring of the A/C switch. If it is High 150 Low 30, check that there is water vapor in the A/C system, repair it, let it dry for about 30 minutes, then refill the gas refill Low-pressure gauge, the pressure drops to the bottom, and then the pressure rises again. High 125 Low 30 I will check the amount of refrigerant/oil, is it high/enough? If High 200 Low 70, there is already a blockage in the A/C system, find the place where the blockage is and replace it. If High 150+ Low>10, the expansive valve is open or there is leakage, you should check the valves.

High 100 Low 100 If the compressor does not stick, the wiring must be checked. Note. The ideal pressure of the A/C system is 150 high and 30 low. I will explain the possible inferences of the A/C system by looking at the level of the high-pressure gauge and low-pressure gauge. If both pressure gauges are low, it is necessary to add more refrigerant gas.

Check if there is any leakage along the pipeline. If the pressure is almost zero, there is a leak. If the low-pressure gauge shows a low condition and the high pressure gauge shows a high condition, it means that you need service. ok, first, I will check whether the expansion valve is blocked or not. I will check whether the tube is an orifice. If the pressure gauge is high on both pressure gauges, air has already entered the A/C system.

When we repair and re-install the A/C, or when we don’t blow all the air out before filling the gas, we experience these kinds of problems and it is already overcharged. If you are going to find the fault after installing the pressure gauge, run the engine at 1500 rpm and set the blower speed to the maximum. Compressor oil is the age of a compressor.

If it says Use only this oil, it is better to use it regardless of its type. If there is a problem with the air corn, it is better to check the whole system. In the wiring section, check whether the fuse / relay is good. Check whether the A/C Amplifier has power. If the power does not come, the clutch does not stick. If the blower fan does not run, check the Fan motor, Fan Speed Resistor, and check the ECU box.

(1) Is there dirt or dirt in the receiver or dryer? (2) Is the expansion valve hole wide? (3) Are the sensing tubes installed incorrectly? (4) Is there leakage of pipes and pipe joints? (5) Is there a leak in the compressor? (6) Condenser fan check. (7) Pressure switch, Control module, Blower fan operating / not. (8) If the fan does not run, the temperature and pressure are high, and the pressure sensor installed in the gas pipe line signals to the ECU that it is overheating, and the magnetic clutch is disengaged. (9) Check air filter good/bad. (10) Are the drive belt fan cables loose? All of the explanations given here are not complete, but I hope you can get the gist of it.